Oil Bottle Mould Customization with Chemical Etching

In a world where presentation and quality are paramount, even the most functional items can benefit from a touch of artistry. The production of oil bottles, a staple in homes and commercial kitchens, is no exception. To meet the growing demand for personalized and visually appealing oil bottles, manufacturers have turned to the magic of chemical etching. In this blog, we’ll explore how etching by chemical is revolutionizing the oil bottle mold customization process, and the intricate artistry behind this innovative technology.

The Essence of Oil Bottle Mould Customization

Oil bottles are ubiquitous in our daily lives, found on kitchen counters and restaurant tables around the world. While their primary function is to store and dispense oil, these bottles have evolved beyond mere containers. They are now a canvas for branding, design and personalization, reflecting the manufacturer’s commitment to quality and aesthetics.

Unveiling the Magic of Chemical Etching

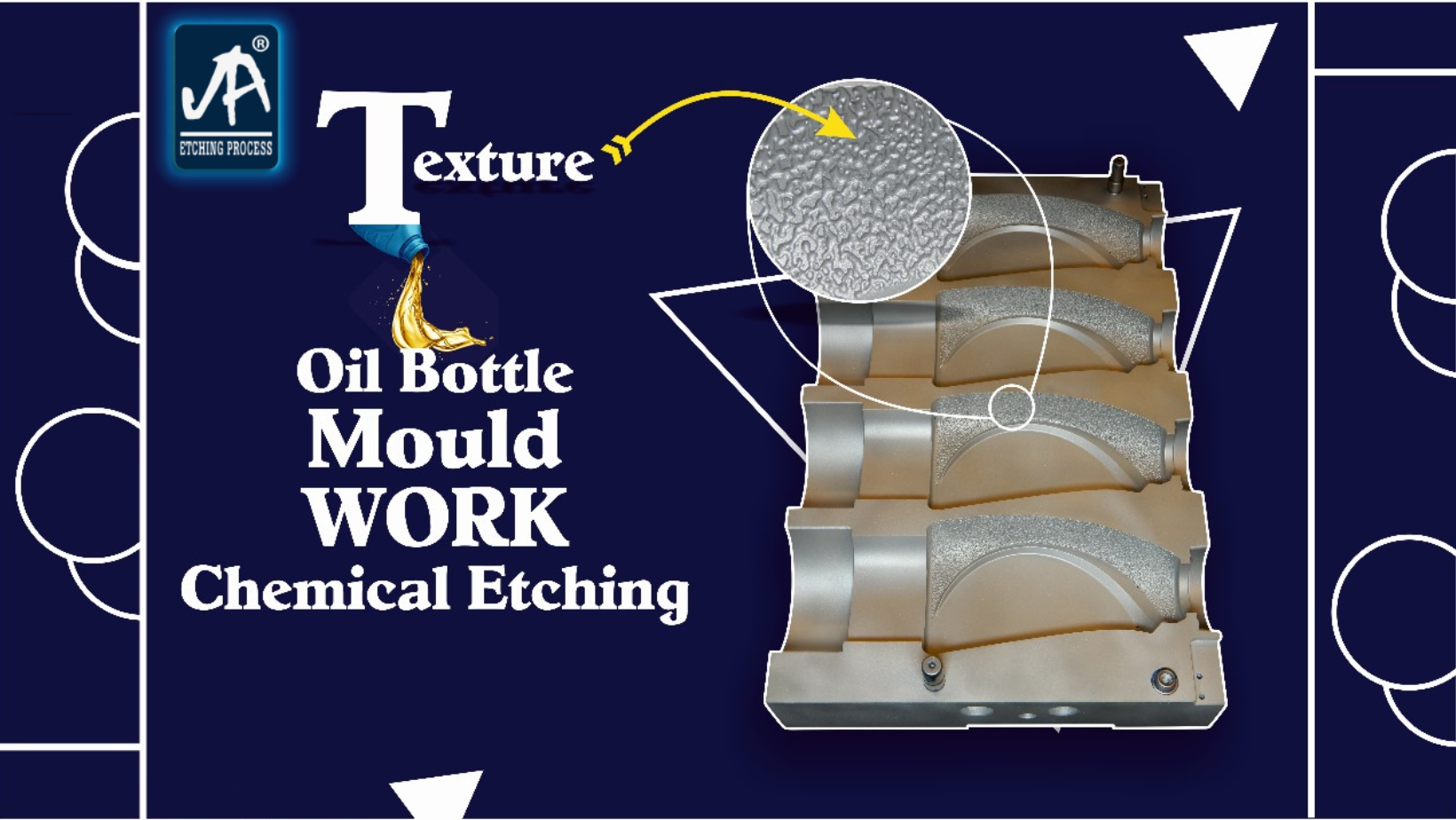

Chemical etching is a precision technique that allows intricate designs, patterns and textures to be engraved on a variety of materials, including metals and plastics. This transformative process uses chemical compounds to selectively remove material from a surface to create detailed and three-dimensional designs.

The Chemical Etching Process:

- Design Creation: The chemical etching process begins with the creation of a digital design that represents the desired pattern or texture.

- Material Selection: Manufacturers select the material for the oil bottle mold, which can be stainless steel, aluminum or other suitable alternatives.

- Surface Preparation: The material chosen is thoroughly cleaned and prepared to receive the etching.

- Masking: A protective mask is applied to the surface, leaving only the areas intended for etching exposed.

- Etching: Chemical compounds are applied to exposed areas, material is selectively removed and the desired design or texture is created.

- Rinsing and Finishing: The etched surface is washed to remove residual chemicals, and the finished product is inspected for quality.

The Artistry of Oil Bottle Mould Customization

Etching in oil bottle mould customization is where functionality meets artistry. This technology offers several benefits:

- Intricate Detail: This allows the creation of intricate designs and patterns that can be as complex as desired.

- Customization: Manufacturers can personalize oil bottle molds with their brand logo, unique patterns or even custom text, making each bottle a work of art.

- Durability: The carved designs are long-lasting and wear-resistant, ensuring that the customized bottles retain their aesthetic appeal over time.

The Future of Oil Bottle Mould Customization

As technology advances, the possibilities for oil bottle mold customization through chemical etching are limitless. Researchers and designers are constantly exploring new ways to increase the depth, complexity and artistic elements of bottle design. The future promises even more creativity and innovation, where each oil bottle is not just a functional container, but also a work of art that adds a touch of beauty to every kitchen.

Conclusion: Where Functionality Meets Artistry

In conclusion, chemical etching has revolutionized the oil bottle mould customization process, adding a touch of artistry to functional containers. The intricate designs and patterns engraved on the bottles reflect a commitment to quality and aesthetics. Oil bottles are no longer just utility items; They have become works of art that enhance the overall experience of their use and display. As technology continues to evolve, the future of oil bottle mold customization promises greater creativity, innovation and artistry, ensuring each bottle is a masterpiece of design and functionality.

_