Electrode Mould Precision: Unveiling the 5-Axis Laser Texturing Magic

In the world of manufacturing, precision is not just a desirable characteristic; This is often the defining factor in the quality of a product. This is especially true in the field of electrical discharge machining (EDM), where even the smallest imperfection in the electrode mold can cause defects in the final product. To meet the industry’s exacting standards, manufacturers have turned to the transformative power of 5 axis laser texturing. In this blog, we will delve into the remarkable world of five -axis laser texturing and find out how this technology works its magic on electrode mould precision.

The Precision Essentials in EDM

Electrical discharge machining (EDM) is a highly specialized manufacturing process used in many industries from aerospace to medical devices. It involves the manufacturing of complex components through the use of electrode moulds. The quality of these moulds directly impacts the accuracy and quality of the final product. Any deviation from mold perfection can result in costly defects and production delays.

5-Axis Laser Texturing: The Game-Changer

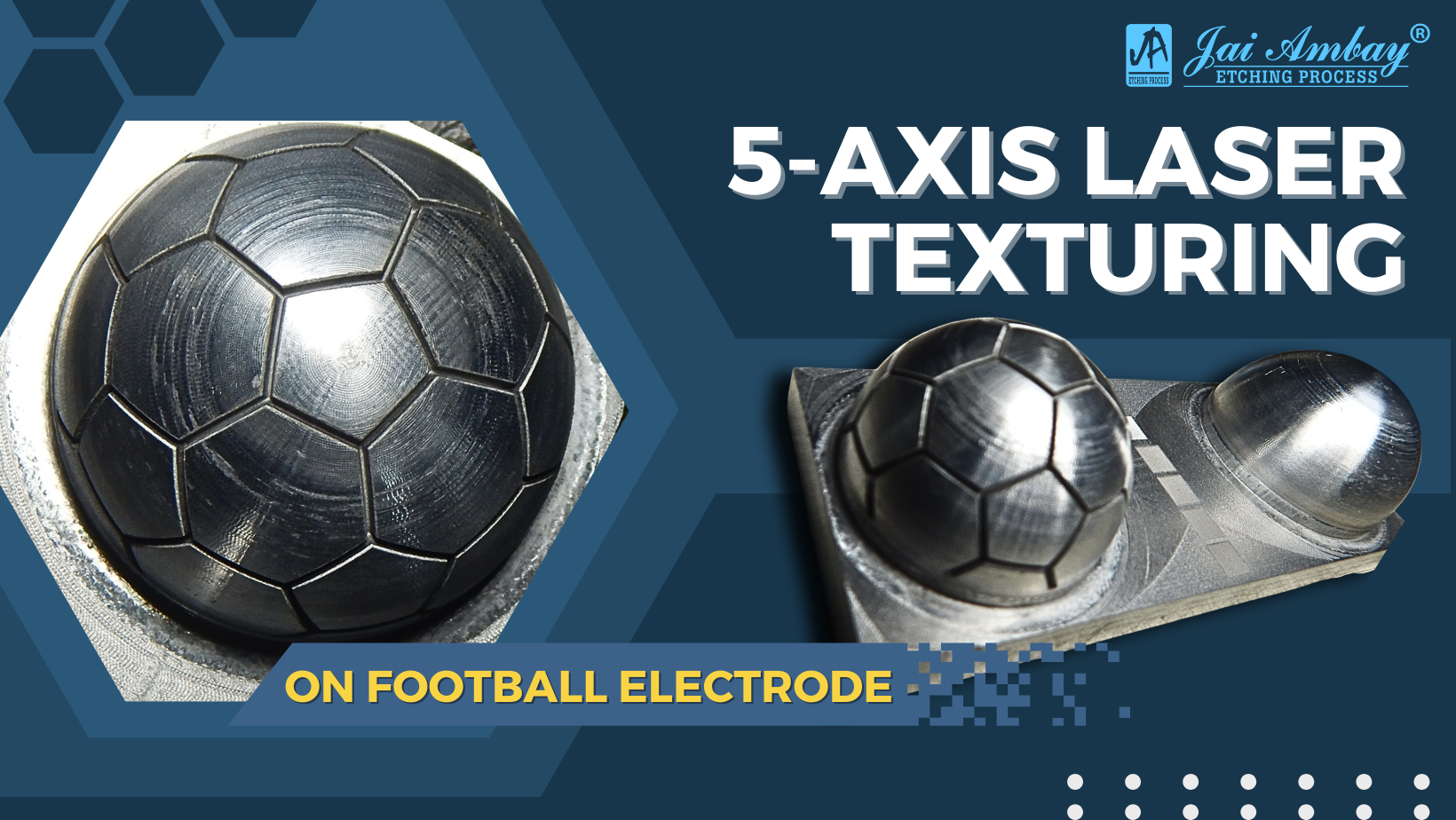

Enter 5 axis laser texturing, a technology that has disrupted the manufacturing landscape, particularly in the production of electrode molds. This cutting-edge technology enables manufacturers to create complex, highly detailed surface textures with unparalleled precision. But how does it work its magic?

The Revelation of 5-Axis Laser Texturing

The term “5 axis” refers to the device’s ability to move in five different directions, providing exceptional flexibility. This technology uses a high-powered laser to engrave complex patterns, textures or designs on the surface of an electrode mold. What makes 5 axis laser texturing truly magical is the ability to apply these textures from multiple angles, increasing their complexity and depth.

The Magic of 5-Axis Laser Texturing:

- Intricate Textures: This technology can create highly complex surface textures, which enhances both the functionality and aesthetic appeal of the electrode mold.

- Multidimensional Precision: The 5 axis movement allows for precise and complex textures from different angles, ensuring uniformity and detail.

- Customization: Manufacturers can tailor the textures to meet specific requirements, whether for medical devices, aerospace components, or any other application.

- Consistency: The precision of this texturing guarantees that each electrode mould is identical, eliminating variation in the production process.

Applications in Diverse Industries

The magic of laser texturing finds applications in various industries, including:

- Aerospace: In the aerospace industry, where precision is paramount, electrode moulds created using five-axis laser texturing ensure the flawless production of complex components.

- Medical Devices: The medical device industry demands the highest level of precision. Electrode moulds manufactured with this laser texturing are indispensable for crafting intricate medical components.

- Automotive: From engine parts to fuel injection systems, the automotive industry relies on electrode moulds that are both precise and consistent, which 5-axis laser texturing delivers.

In Conclusion: The Magic of Precision

In conclusion, 5-axis laser texturing is a technological marvel that is revolutionizing the world of electrode mould manufacturing. This elevates the functionality and precision of molds to a new level, transforming them from mere tools to pieces of craftsmanship. As this technology continues to advance, we can expect to see a future where electrode moulds are not only precise but also works of art, reflecting the dedication and innovation of the manufacturing industry. 5-axis laser texturing is where precision meets artistry, creating tools that are as functionally exceptional as they are stunning to look at.

…