Chemical Etching: Elevating Metalwork to New Heights

Introduction

In the world of metalwork, precision and creativity go hand in hand. A breakthrough technology called as chemical etching has arisen to generate stunning patterns that fascinate the eye. This process, provided by specialised chemical etching company, transforms everyday pieces of metal into breathtaking works of art by combining the power of chemistry and technology. In this blog article, we’ll go into the world of chemical etching company and see how they’ve taken metalwork to new heights.

The Science Behind Chemical Etching

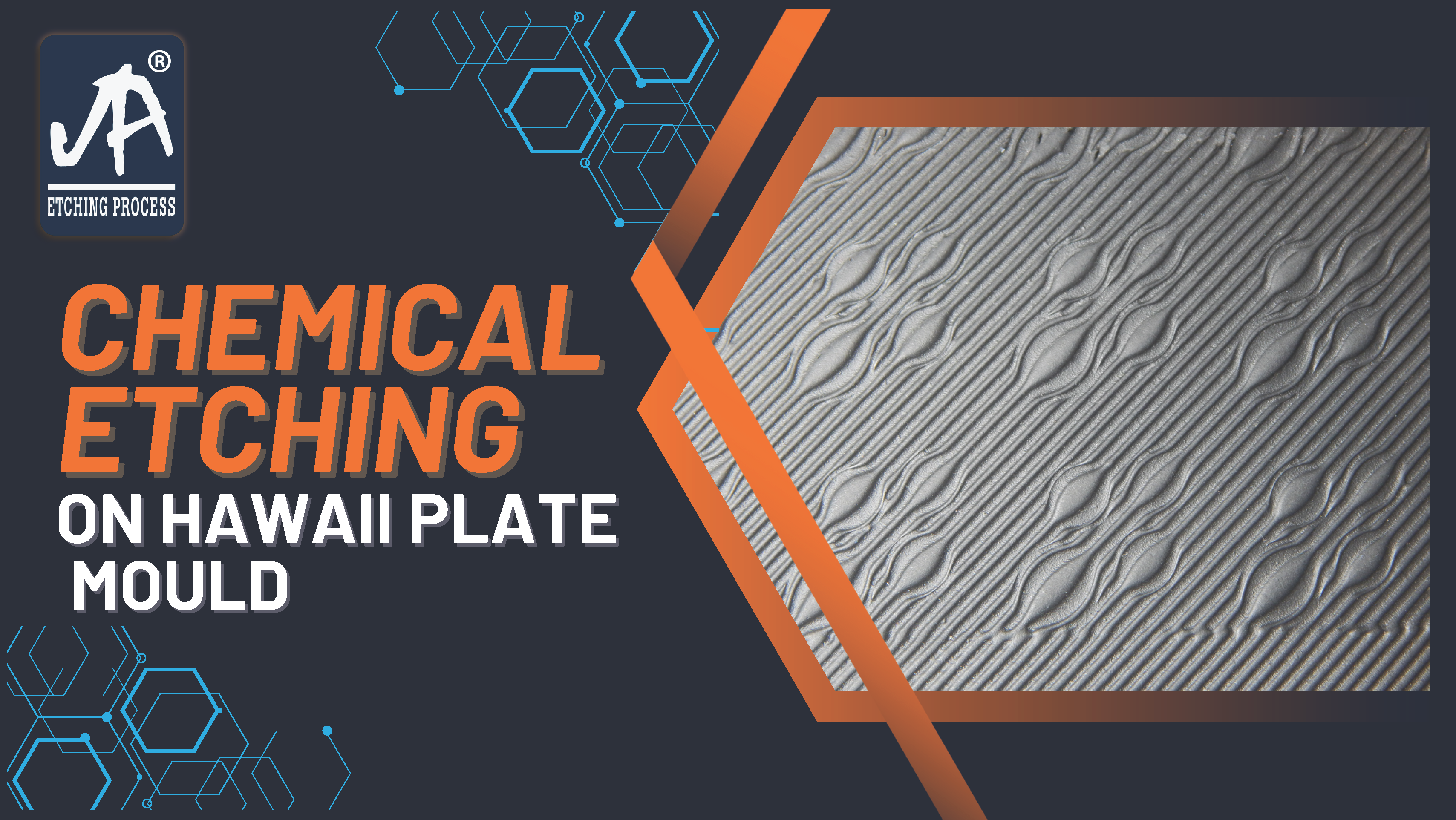

Chemical etching, also known as photochemical etching, is a subtractive metalworking method that removes material from a metal surface selectively using corrosive chemicals. The procedure starts with the fabrication of a precise stencil, also known as a mask or photoresist, which is then applied to the metal surface. The masked metal is then subjected to a chemical solution, which depletes the unprotected parts and leaves the desired design or pattern behind.

The Advantages of Chemical Etching

- Precision: Chemical etching makes it possible to create detailed and accurate designs that would be difficult to produce using traditional procedures.The high level of detail achievable through this process allows to production of complex geometries, fine lines, and even micro-sized features.

- Versatility: It may be used on a variety of metals, including stainless steel, copper, brass, and aluminium. Because of its adaptability, it is appropriate for a wide range of sectors, including electronics, jewellery, medical devices, and automobiles.

- Cost-effectiveness: It is a cost-effective solution for small to medium-sized manufacturing runs.Unlike traditional machining methods, which often require expensive tooling and setup, chemical etching eliminates the need for costly moulds or dies, resulting in significant cost savings.

- Quick Turnaround Time: This service has a quick turnaround time, making it appropriate for tasks with short deadlines. From concept to manufacturing, the simplified process offers a speedy and effective production cycle, allowing businesses to satisfy their consumer requests quickly.

The Role of Photochemical Etching Companies

Photochemical etching companies play a vital role in the manufacturing industry by providing precise and efficient metal etching solutions. Jai Ambay Etching Process uses innovative techniques to generate elaborate patterns, designs, and components on diverse metal surfaces using the photochemical etching process.

The primary function of photochemical etching companies is to offer cost-effective alternatives to traditional machining methods. They specialise in producing high-quality, burr-free components with remarkable precision and reproducibility. As a result, they are appropriate for use in sectors such as electronics, automotive, medical devices, and others.

To obtain the required results, the chemical etching company employs a variety of stages including design, photoresist application, exposure, development, and etching. They use specialised equipment, chemicals, and skills to remove metal from the substrate selectively while maintaining strict tolerances and the material’s integrity.

These firms enable the manufacturing of complicated components, complex geometries, and micro-sized features that would otherwise be difficult to fabricate by utilising metal chemical etching services. Their contributions to producing custom-made components with rapid turnaround times and high precision greatly improve the efficiency and performance of a wide range of products and technology in a variety of sectors.

Conclusion

Chemical etching has transformed the metalworking industry, driving it to new heights of accuracy, adaptability, and invention. Chemical etching companies provide a unique and cost-effective option for generating elaborate and precise metal patterns by combining chemistry and technology. This unique method motivates artists, engineers, and designers to explore new horizons and rethink what is possible in their respective professions as it continues to expand and push the boundaries of metallurgy. ,