Innovation in 3D Surface Etching: A Transformative Journey in Mould Manufacturing

Driven by innovation and the pursuit of perfection, manufacturing continues to evolve. One of the most exciting developments in recent years is the combination of mold-making artistry and precision that metal etching companies and 3D laser engraving bring to the table. In this blog, we explore the fascinating field of 3D surface etching innovation and its impact on moulds.

The Intersection of Art and Precision

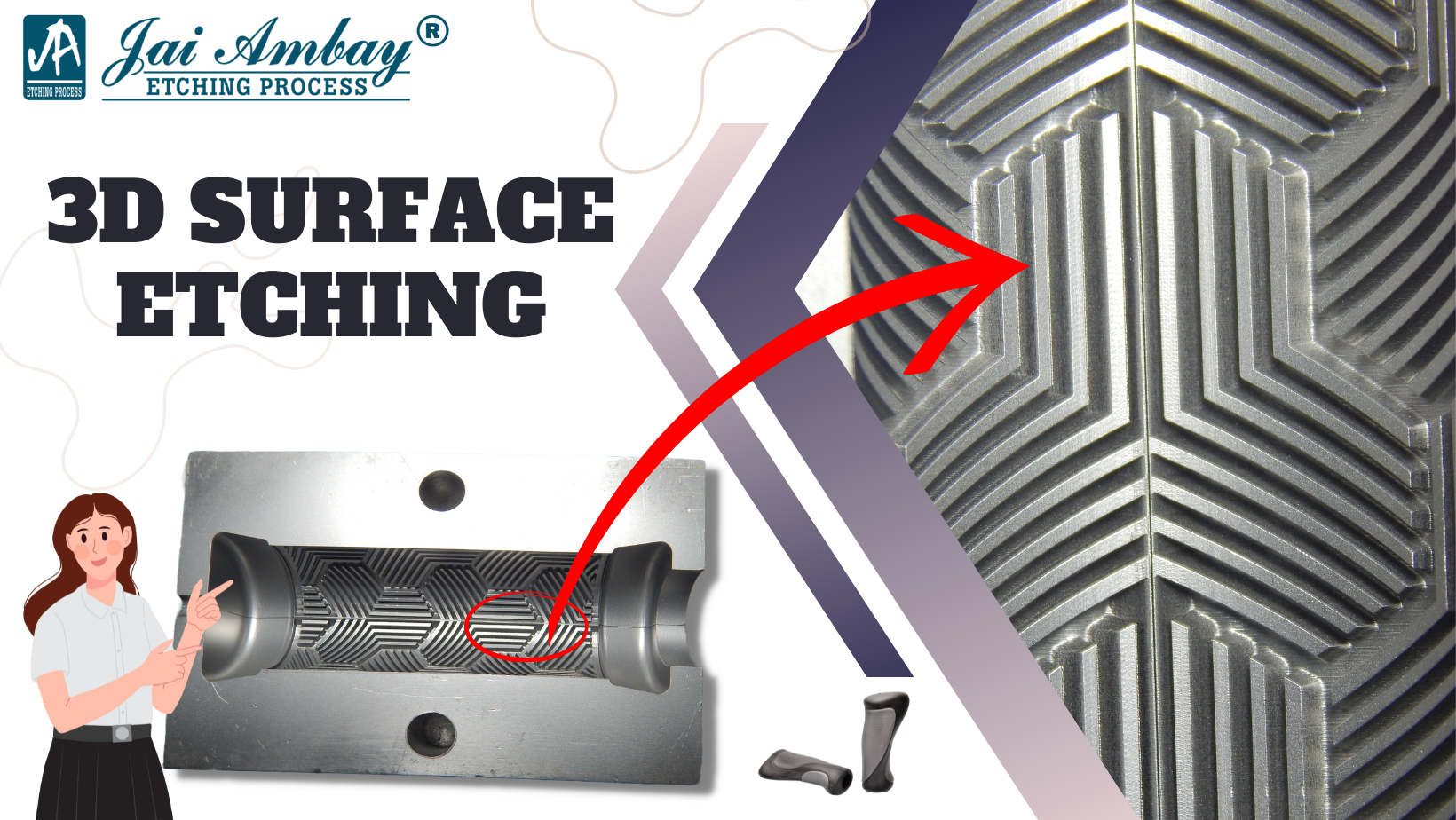

Traditionally, molds have been viewed as functional parts with little room for aesthetic expression. However, with the advent of 3D surface etching, this perception has changed dramatically. This cutting-edge technology enables manufacturers to incorporate intricate and fascinating designs into their molds, transforming them from mere tools to works of art.

Metal Etching Companies: Pioneers of Precision

At the heart of this transformation are metal etching companies. These specialized firms have perfected the art of precision in etching metal surfaces. Their expertise lies in meticulously etching patterns, designs, and textures onto metal, creating astonishing visual and tactile effects.

The Marvel of 3D Laser Engraving

3D laser engraving is one of the cornerstones of this innovative approach. This technique employs laser technology to etch designs onto metal surfaces with unparalleled precision. The result is a three-dimensional masterpiece that elevates the aesthetics of moulds to unprecedented levels.

The Impact on Mould Manufacturing

The infusion of 3D surface art into mould manufacturing has a profound impact. Here’s how:

- Aesthetic Excellence: Moulds are no longer plain and utilitarian. They become visually striking, adding a touch of elegance to the manufacturing process.

- Brand Identity: Customized designs and logos on moulds strengthen brand identity, making products instantly recognizable.

- Increased Value: Moulds with intricate 3D surface art are perceived as premium, adding perceived value to the products they shape.

- Texture and Functionality: 3D surface etching can also enhance the texture of moulds, improving their functionality in specific applications.

The Process Unveiled

The process begins with collaboration between designers and metal etching experts. Once a design is finalized, 3D laser engraving comes into play. The high-powered laser meticulously etches the design onto the mould’s surface, creating depth, texture, and visual appeal.

Metal Etching Companies: The Architects of Artistry

Metal etching companies bring decades of expertise to the table. They understand the intricacies of etching, including material compatibility, design feasibility, and precision. Their role is pivotal in translating a concept into a tangible work of art on metal surfaces.

3D Surface Art: A Glimpse into the Future

The potential of 3D surface art in mould manufacturing is limitless. As technology continues to advance, we can anticipate even more breathtaking designs and textures that will redefine the possibilities of product aesthetics. Moulds will no longer be hidden in the manufacturing process; they will take centre stage as visual and functional marvels.

Conclusion: Elevating Mould Manufacturing to an Art Form

“Innovation in 3D Surface etching” has led in a new era in mould manufacturing. It’s a testament to how technology, artistry, and precision can converge to create beauty even in the most functional of objects. With the expertise of metal etching companies and the precision of 3D laser engraving, moulds have transcended their utilitarian role, becoming captivating pieces of art that shape the products we love. This transformation not only enhances product aesthetics but also strengthens brand identity and value, offering a glimpse into a future where manufacturing is not just about function but also about artistry.

..